UFLA files international patent for automated system in agricultural grain processing machines

The Federal University of Lavras (UFLA), through the Directorate of Innovation and Technology (Dintec) and its Center for Technological Innovation (Nintec), filed a new international patent regarding the development of a technology aimed at the automation and monitoring of agricultural machinery for grain processing. The registration was carried out in Brazil, in 2024, and in Colombia, in July 2025, expanding the international reach of the protection of the invention. This is UFLA’s fourth international patent filing.

The official title of the patent is “Automated system to control an agricultural machine; method of monitoring, detecting and locating faults in an agricultural machine; fault detection and location system in an agricultural machine and automated grain processing agricultural machine”.

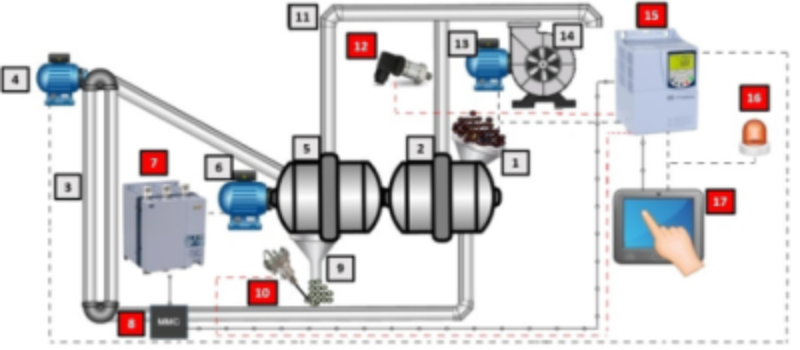

General structure of the proposed control and monitoring system

The team responsible for developing the technology is made up of professors from the School of Engineering (EEng) Danton Diego Ferreira and Bruno Henrique Groenner Barbosa, coordinators of the Center for Innovation in Automation and Artificial Intelligence (AIA/UFLA); the post-doctorate in Agricultural Engineering and coffee specialist Luiz de Gonzaga Ferreira Júnior; and by engineer Israel Andrade Lima, graduate of the master’s degree in Systems Engineering and Automation (PPGESISA/UFLA). The partnership also had the collaboration of the company Pinhalense, a reference in the agribusiness equipment sector.

Problem solved by technology

Coffee bean processing involves the removal of impurities through suction systems. In traditional solutions, the pressure control in the pipes is done manually, with mechanical levers, depending heavily on the operator’s experience. This method can cause loss of grains along with impurities, as well as failures in operation and risks to the equipment.

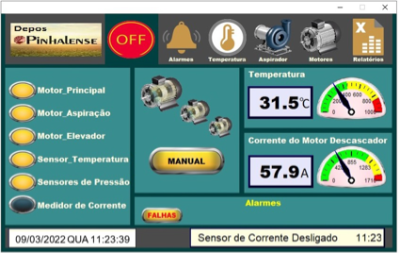

The UFLA patent presents an innovation by automating this process, through an intelligent pressure control system that optimizes suction, avoiding grain loss. In addition, an automated system for monitoring, detecting and locating faults was developed, which monitors variables such as voltage, current, pressure and temperature, identifying problems in real time. The system records the events in an intuitive and easy-to-interpret Human-Machine Interface (HMI), and acts with sequential interlocking of the machine, which ensures that the machine only advances to the next stage when the previous one is completed and safe, preventing damage to the equipment, the product and the operator. The HMI interface also signals to the user where there are faults so that the operator can check.

HMI (human-machine interface) developed

The innovative character of the technology lies in the complete automation of processes that, until then, were manual. The system combines operational efficiency, safety and precision, characteristics that raise the standard of grain processing machines. Its use is not limited to coffee: the solution can be applied to any grain processing machine that operates with impurity aspiration systems, expanding its potential impact on agribusiness.

The economic impact is considered significant, as the intelligent automation of pressure control reduces grain losses during processing and enhances their quality, which generates a direct yield increase for the producer. In addition, the real-time monitoring system reduces the need for unscheduled stops and reduces corrective maintenance costs, extending the useful life of the equipment. “For manufacturers of agricultural machinery, the incorporation of this technology can add competitive value to their products, differentiating them in the market and opening space for the export of more technological equipment. At scale, the reduction of waste and operational failures represents relevant savings for the agribusiness chain,” says Professor Danton.

According to the professor, the initial focus tends to be on large industries, since they have a greater capacity to invest in automated machinery and generally deal with production volumes that amplify losses resulting from manual failures. “However, with time and the possible adaptation of the technology in more accessible versions, small and medium-sized producers will also be able to benefit, mainly by reducing waste and supporting the operator via an intuitive interface, which reduces the dependence on highly specialized labor,” he explains.

Contact

Interested in more information about the technology or in future partnerships can contact the UFLA Innovation and Technology Directorate (Dintec), by e-mail: comunicacao.dintec@ufla.br.